Exactly How an Optical Fibre Diameter Analyser Improves Quality Assurance in Fibre Manufacturing

The assimilation of an Optical Fibre Diameter Analyser into Fibre manufacturing processes stands for a considerable advancement in high quality control methodologies. By using real-time, accurate dimensions of Fibre sizes, this technology attends to the critical requirement for uniformity in manufacturing standards.

Significance of Fibre Diameter Measurement

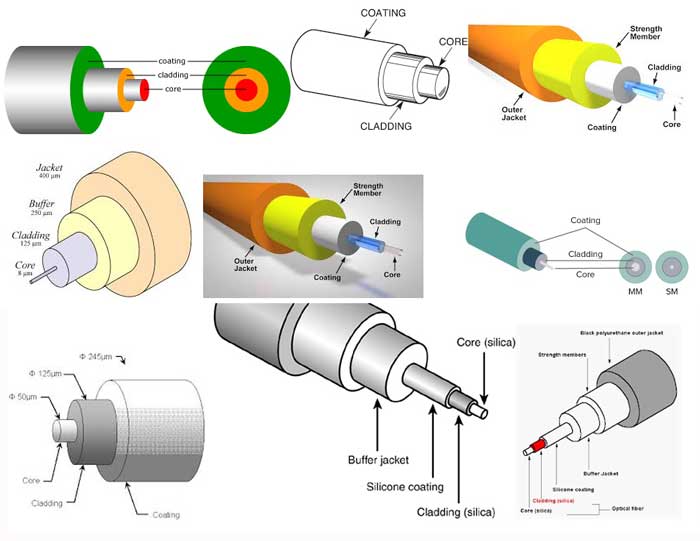

Precise measurement of Fibre Diameter is essential in the field of optical Fibre technology, as it directly influences the performance and dependability of Fibre optic systems. The Diameter of an optical Fibre affects its light-carrying capacity, attenuation, and total transmission performance. Accuracy in gauging Fibre Diameter makes sure that the optical properties are kept within defined resistances, which is crucial for ideal signal integrity.

Variations in Fibre Diameter can bring about raised losses as a result of spreading and modal diffusion, affecting the quality of data transmission. In high-speed interaction systems, such disparities can result in significant destruction of signal top quality, resulting in information mistakes and decreased performance. Moreover, regular Fibre Diameter is vital for compatibility with ports and splicing innovations, which are indispensable components of Fibre optic networks.

Quality assurance processes in Fibre production greatly depend on accurate Diameter measurements to make certain compliance with sector requirements. By implementing durable measurement strategies, producers can boost product integrity, reduce waste, and boost general system performance. Thus, the value of Fibre Diameter measurement can not be overemphasized, as it works as a foundation in the advancement of optical Fibre modern technology and its applications in contemporary interaction networks.

How the Analyser Functions

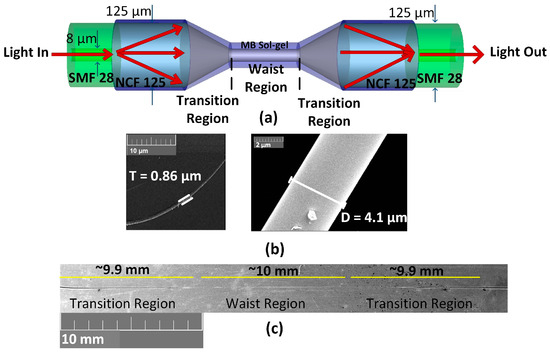

The effective measurement of Fibre Diameter depends on innovative analytical strategies that guarantee accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a mix of laser modern technology and advanced picture handling formulas to accurately examine the Diameter of fibers as they are produced

Originally, a laser beam of light is routed at the moving Fibre, developing a cross-sectional darkness. The analyser captures this shadow utilizing high-resolution electronic cameras positioned tactically along the manufacturing line. The recorded images are then processed in real-time to figure out the Fibre's Diameter with outstanding precision.

The system makes use of sophisticated algorithms that represent different aspects, consisting of variants in light strength and ecological problems, to boost dimension integrity. It can detect minute changes in Diameter, such as variations that might occur during the manufacturing process.

Moreover, the analyser can taking care of numerous fibers simultaneously, increasing throughput without endangering precision. By supplying instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays an essential function in preserving stringent quality assurance requirements, making certain that the last product meets sector requirements and client requirements.

Advantages of Real-Time Tracking

While conventional methods of checking Fibre Diameter usually include time-consuming post-production checks, real-time surveillance significantly enhances the efficiency and high quality of optical Fibre production. optical fibre diameter analyser. This positive approach permits makers to identify inconsistencies in Fibre Diameter as they happen, as opposed to waiting till production is full to evaluate top quality

By constantly gauging the Diameter throughout production, suppliers can guarantee that the fibers satisfy stringent specs, resulting in reduced variability and boosted consistency. Real-time surveillance likewise enables prompt rehabilitative actions to be taken, reducing waste and preventing faulty fibers from entering the supply chain.

Additionally, this modern technology facilitates improved information collection and evaluation, offering understandings right into production fads and potential locations for improvement. Such data-driven decision-making empowers makers to maximize processes and maintain high requirements of top quality control.

Furthermore, real-time monitoring promotes a culture of constant renovation within the manufacturing environment. Employees are much more engaged when they can see the effect of their operate in real-time, leading to heightened responsibility and a commitment to excellence. Generally, the execution of real-time monitoring systems in optical Fibre manufacturing equates to remarkable item top quality and raised customer Learn More Here contentment.

Effect On Production Effectiveness

Carrying out optical Fibre Diameter analysers significantly enhances manufacturing efficiency by enhancing the production process. These gadgets assist in continual monitoring of Fibre Diameter, enabling producers to discover discrepancies in real-time. By determining disparities quickly, assembly line can be adjusted quickly, decreasing browse around these guys downtime and lowering the chance of generating faulty products.

Furthermore, the assimilation of these analysers right into the production operations makes it possible for much better resource appropriation. With precise Diameter dimensions, drivers can enhance material use, making certain that resources are not wasted on flawed fibers. This precision also adds to much less remodel and scrap, eventually lowering manufacturing expenses.

The automation offered by optical Fibre Diameter analysers reduces dependence on manual inspections, which are prone and usually taxing to human error. Consequently, employees can concentrate on more strategic jobs, improving overall productivity.

In addition, the data created from these analysers can notify process renovations and promote far better decision-making. By analyzing patterns in Fibre Diameter variants, producers can implement positive actions to enhance manufacturing strategies and maintain constant top quality. In recap, optical Fibre Diameter analysers play a crucial function in enhancing production effectiveness, bring about higher high quality result and increased success.

Study and Success Stories

Across various industries, study highlight the transformative influence of optical Fibre Diameter analysers on production processes. One famous example is a leading telecommunications business that dealt with obstacles with inconsistent Fibre diameters, bring about enhanced being rejected prices. By incorporating an optical Fibre Diameter analyser, the company accomplished real-time surveillance of Fibre measurements, resulting in a 30% reduction in problems and considerable expense savings.

Moreover, a research establishment focusing on innovative materials made use of optical Fibre Diameter analysers to fine-tune their speculative processes. The analyser's capacity internet to supply detailed understandings into Fibre consistency allowed the development of ingenious products with enhanced efficiency qualities.

These success stories highlight the important duty of optical Fibre Diameter analysers in improving top quality control, enhancing manufacturing effectiveness, and driving technology across varied industries.

Final Thought

To conclude, the Optical Fibre Diameter Analyser plays a pivotal role in improving quality control within Fibre manufacturing. By offering specific, real-time measurements and facilitating instant corrective activities, this technology substantially lowers variability and decreases waste. The application of such innovative tools promotes a society of continuous enhancement and functional efficiency, eventually ensuring compliance with market criteria and preserving competition. As demonstrated with various study, the analyser proves vital for attaining exceptional item top quality in Fibre manufacturing.

The application of optical Fibre Diameter analysers permitted for rigid quality control, making sure that the produced fibers met exacting sector requirements.In verdict, the Optical Fibre Diameter Analyser plays a critical duty in enhancing high quality control within Fibre production.

Comments on “Why Every Fibre Optic Manufacturer Needs an Optical Fibre Diameter Analyser for Quality Control”